Home » Posts tagged 'plumbing guide'

Tag Archives: plumbing guide

The Importance of a Reliable Sump Pump

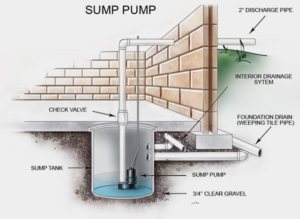

Many homes are protected by a sump pump, an unassuming but crucial device that quietly safeguards properties against flooding and excess moisture. However, even this simple device can be prone to several issues.

A pump overload can damage the pump, and clogged discharge lines are problematic. Thankfully, these problems can be easily addressed with the right maintenance and monitoring. Contact Sump Pump Aurora CO now!

Water-powered pumps offer a reliable backup for home flood prevention. Their operational independence from electricity means they continue to run even when power is cut. Their energy efficiency saves homeowners money on utility costs over time. Unlike battery-powered backup sump pumps, which must be replaced every three years, water-powered pumps last as long as they continue to work properly.

A water-powered pump is powered by your home’s municipal water supply, which is connected to the pump by a valve and a suction pipe. When triggered by a second float switch within the sump pit, positioned higher than the primary pump’s float switch, the water-powered pump uses high water pressure from the municipality to move the municipal water through the pump jet and then discharge it outside your home. Using the Venturi effect, this process causes your municipal water to draw up the collected water from your basement into its flow. It expels it out of your home, without the need for electrical power.

Since water-powered pumps don’t use a battery, they can operate for as long as your home has a continuous supply of municipal water pressure. However, as your house’s plumbing system ages, you may experience reduced water pressure that impacts the performance of your sump pump.

As with an electric backup sump pump, water-powered pumps can require some regular maintenance, such as checking and replacing the battery, ensuring proper electrical connections, and examining motor efficiency. But these routines are much less frequent than those required for battery-powered pumps, which can take up to a full day to complete and can be expensive to replace when batteries degrade.

In addition, water-powered pumps need periodic inspections of their float switches to ensure they are functioning properly. If the float is obstructed, it can cause your pump to continuously run, which can cause the pit to overflow. In most cases, the pump should only run when the float is engaged and the pump’s discharge valve opens, preventing the pit from filling up too high and flooding your home. You may be required to have a backflow preventer installed on your water line so that the pump doesn’t pollute the potable household water supply.

Electric Pumps

When pumping fluids, whether it be oil or water, mechanical pumps are commonly used. However, electric pumps have gained traction for many applications because they are reliable, require less maintenance and generate less heat. Electric pumps can also provide greater flexibility and precision than mechanical ones, especially for applications where the fluid demands are constantly changing, such as lubricating equipment.

Electrical pumps are powered by an electric motor which is connected to the pump suction flange via a shaft. This eliminates the need for a flow control component, saving manufacturing costs. Electric pumps can also be designed to precisely match the pump output to the flow requirements of the machine they are lubricating, reducing energy consumption.

A sump pump is designed to prevent the flooding of a basement or crawl space by pumping out excess water. It is essential that the pump be installed correctly, which is why it’s a good idea to hire a licensed and experienced plumbing contractor for the job. In addition, the pump should be plugged into a dedicated circuit that is not shared with other appliances. This makes it less likely that power will be lost due to a blown fuse or tripped circuit breaker.

There are two main types of sump pumps: submersible and pedestal. While submersible pumps are fully submerged in the water, pedestal pumps have their motor above the sump basin. Pedestal pumps are typically louder and take up more room than submersible pumps, but they offer a number of advantages including easy access for maintenance.

Regular maintenance of a sump pump is critical to its longevity and performance. A flooded basement or water damage can be very costly, and it’s a good idea to have a professional inspect your pump regularly for signs of wear or failure.

Depending on the type of sump pump, there are different maintenance tasks that should be performed to ensure the safety and proper function of the system. Inspecting the pump for leaks is important, as well as ensuring that the weep hole is free from obstruction and that the float switch and pressure switch are working properly.

Low-Voltage Pumps

If you have a basement or crawl space that is prone to flooding, sump pumps are very important in keeping water from building up under your house. This prevents structural damage and keeps the area clean and safe for your family to use. This also protects against mold, wood rot, and pests that could otherwise cause problems for you and your family. In addition, it will help keep the value of your home up and may make it easier to sell in the future.

A sump pump works using a float switch that is activated when the water level rises above a predetermined amount in your sump pit. The switch is connected to an electric motor that uses an impeller to rapidly spin, creating a low-pressure area that draws the water into the pump and then out of your discharge line. The discharge line is cored through your wall and siding, and it drains away from the foundation of your house.

There are a number of different types of pumps available. Some are submersible and others sit on a pedestal above the sump pit and basement water line. Pedestal pumps allow for some of the water to enter the pump and naturally re-absorb into the ground before it is pumped out, which can reduce the frequency that your sump needs to operate.

You can also find pumps that have built-in alarms, automatic switch mechanisms, and adjustable float switches. Some even have silencing check valves that are designed to reduce the noise produced by the pump as it runs. In addition, you will want to consider the quality and durability of the pump when choosing which one to purchase.

You will also need to determine where you will need your pump to drain water to. It is best to discharge it in an area that is downhill and away from your house, but some areas have a difficult time draining because of the composition of the soil or the grade of the land. In these cases, it is best to install downspout extensions so that the water can drain farther away from your house than it normally would without a sump pump.

High-Voltage Pumps

In addition to preventing flooding and water damage, sump pumps help eliminate mold and other organisms that thrive in moist conditions. These organisms can be detrimental to the health of your family and can even lead to serious illnesses such as cancer. In addition, a well-functioning sump pump helps prevent these organisms from spreading into your house, where they can damage electrical wiring and cause fires.

To keep your basement dry, your sump pump is constantly working to remove water from the lowest point of your home – the sumps. It is important to have a well-functioning pump that is large enough to handle the amount of water your property collects. It is also important to have a backup option, such as a battery-powered system or an additional sump, to ensure that the pump will be able to operate in the event of a power outage or during severe storms.

Many residential sump pumps are located in a pit or basin underneath the basement floor, where it is designed to collect the water from the area. This is necessary because water that accumulates in your basement can leak into the foundation of your home and create serious problems such as a sagging floor, structural instability, or even flooding of your entire house. This type of pump is also used in industrial and commercial applications to control ground saturation, which can affect the stability of surface soil and may cause ponding or flooding.

A sump pump is powered by an electric motor, which activates the pump when a float switch rises to the appropriate level of the pumped liquid. Once the float switch is activated, it will power an impeller or small fan-like device that quickly spins to draw the water into the motor and then discharges it through your discharge line. The discharge line is cored through your basement or exterior siding and then runs away from the house, directing the water outside where it will not return to the home.

There are several types of switches available for triggering the pump, including diaphragm pressure sensors and electronic switches that use capacitance or conductance technology to sense changes in water levels. These switches offer more precise control over the activation and deactivation points, and they are less prone to mechanical issues compared to float switches that are attached to the end of a short length of flexible cable, which can get tangled or obstructed in your sump basin.